Leading Tips for Effective Electric System Troubleshooting

Fixing electric systems needs a systematic technique, grounded in a detailed understanding of electric concepts and safety protocols. The nuances of efficient fixing prolong beyond simple technological understanding; understanding just how to document searchings for and focus on security can dramatically affect results.

Understand the Essentials

Recognizing the fundamentals of electrical systems is important for reliable troubleshooting, as a strong foundation allows specialists to detect and settle problems more successfully. A detailed grasp of electrical concepts, such as voltage, current, resistance, and power, is crucial in recognizing the origin of problems. Voltage is the electric possible distinction that drives present through a circuit, while resistance opposes the flow of present, affecting the general performance of the system.

Experience with circuit components, including resistors, capacitors, diodes, and switches, is also extremely important. Each element plays a distinctive function in circuit behavior and can influence performance when malfunctioning. Additionally, recognizing collection and identical circuit arrangements is essential, as these arrangements influence the distribution of voltage and present within the system.

Moreover, expertise of safety protocols is important. Professionals have to know potential hazards, such as shock and brief circuits, to carry out risk-free troubleshooting practices. By understanding these foundational concepts, technicians boost their capability to carry out reliable diagnostics and repair work, inevitably resulting in enhanced performance and reliability of electric systems. This fundamental expertise is the foundation of effective troubleshooting undertakings.

Gather Necessary Equipment

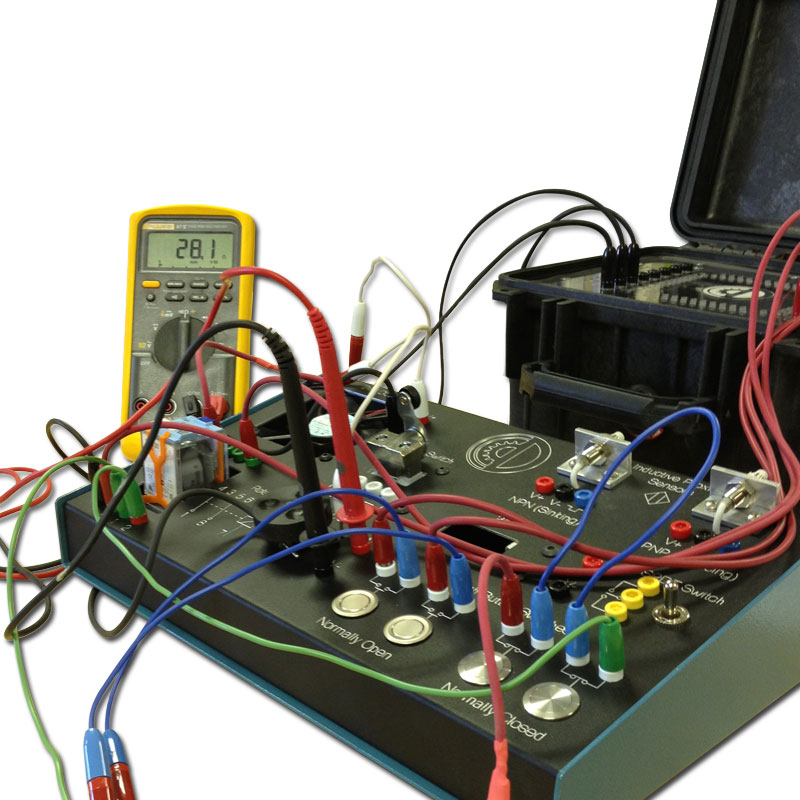

Effective troubleshooting of electrical systems calls for the best collection of tools to identify and deal with concerns properly. A fully equipped professional can considerably improve performance and efficiency in determining problems. Important devices include a multimeter, which measures voltage, current, and resistance, permitting for exact evaluations of electric parts. Secure meters are also beneficial for determining current without disconnecting the circuit, ensuring safety and security and convenience.

In addition, shielded hand devices such as screwdrivers, pliers, and cord strippers are important for safely manipulating electrical connections. It is also a good idea to have a circuit tester accessible to confirm the presence of voltage in outlets and wires. For more complex systems, a thermal imaging camera can assist spot overheating parts, showing possible failures.

Follow a Systematic Strategy

Having actually collected the appropriate devices, the following action in troubleshooting electrical systems is to follow an organized technique. A systematic approach ensures that service technicians can recognize faults effectively and properly, click for more info lessening downtime and stopping unneeded repairs.

Begin by reviewing the system's schematic diagrams and specs. This entails monitoring each part methodically, beginning from the power resource and functioning towards the load.

Use testing tools, such as multimeters and oscilloscopes, to gather objective data about voltage, current, and resistance at various factors within the system. This empirical proof will certainly assist your troubleshooting initiatives and assist to confirm or eliminate potential causes of failure.

Furthermore, think about environmental elements that might affect the system's performance, such as temperature level fluctuations or moisture ingress. A thorough inspection of circuitry, links, and parts will make sure that all possibilities are made up.

Document Your Searchings For

Comprehensive documentation is essential in the troubleshooting process of electrical systems. This technique not just help in recognizing the origin reason of the trouble however additionally serves as a referral for future troubleshooting initiatives.

In addition, preserving a log of components changed or fixings performed is very useful. This information supports stock administration and can aid analyze the longevity and reliability of certain components.

Inevitably, the paperwork procedure should be detailed yet succinct, allowing very easy retrieval and review - electrical system troubleshooting. By focusing on in-depth documents, professionals can produce a beneficial expertise base that not just aids in existing troubleshooting however likewise empowers future upkeep initiatives, thereby boosting total system integrity

Prioritize Precaution

Identifying the fundamental risks linked with electrical systems is crucial for making certain security throughout troubleshooting. Electric shock, useful source burns, and equipment damages are just a few of the possible dangers that technicians encounter. Focusing on precaution is not only a lawful responsibility but also an ethical important that safeguards both the technician and the surrounding atmosphere.

Before starting any type of troubleshooting task, technicians must put on appropriate individual safety tools (PPE), including protected gloves, shatterproof glass, and flame-resistant clothing. Making certain that the workspace is dry and complimentary of mess can dramatically reduce the danger of accidents. In addition, it is necessary to de-energize circuits before beginning any type of job, confirming that they are not endure click for more info making use of a multimeter or voltage tester.

Developing clear interaction procedures with staff member is also vital; this makes certain that everybody recognizes prospective threats and the condition of the electric system being worked with. Having an emergency situation response plan in location can verify important in the event of an occurrence. By focusing on safety and security actions, specialists can properly alleviate dangers and promote a more secure office.

Final Thought

Reliable electrical system fixing relies on a thorough understanding of essential principles and a systematic method. Prioritizing security measures guarantees the wellness of people included and the stability of the electric system.